Every truck, every construction machine has it: The acoustic alarm that warns people behind the vehicle when it is reversing. But is it enough in a steel mill, on a construction site or in mining, where high noise levels cannot be avoided?

Do the drivers of other machines always hear the alarm in their noise-protected cab? And what about the colleagues who protect their ears with earplugs? Or the crane operator in his pulpit far off under the hall roof?

A simple solution for more safety

With a simple solution, we increase occupational safety considerably: with the projection of luminous red light strips onto the floor around the rear end and the sides of the machine, which can hardly be overseen. They show that the machine is in operation or moving. In terms of function, they are comparable to the black and yellow safety floor markings that demarcate danger zones. But they follow every movement of the machine … hence “ride-on”.

The Blue Spot

For situations where it is sufficient – for example, when the noise level is low – to warn of reversing machines, we project a blue light spot onto the ground behind the vehicle. In this way, people coming from the side recognise that the driver of a machine is backing up.

All-round safety without blind spots

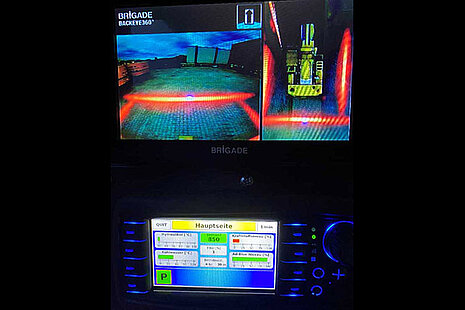

But it’s not just about being seen: The 270 ° camera system allows the operator to see what is happening around his machine with an environment view on the screen in the driver’s cab, this way the operator can react immediately.

“Since our machines have been equipped with the optimally available projectors, there have not even been any near-collisions at all.”

Alexander vom Bey

Development/Design, TML Technik GmbH

Do you have any questions about our machines and applications?

Contact us!

Volker Bongardt Telefon: +49 173 5461091

Metallurgie Mail: v.bongardttmlde